|

1551 S. Harris Court, Anaheim, CA 92806 Anaheim, CA 92806

Phone: 714.978.1551  Fax: 714.978.0431 Fax: 714.978.0431

Specifications: Model 7300C Series, Single Head Die Bonders, Manual X-Y-Z Last revised: 5/24/2010

Series Overview

Application and Function :

Machines of this series enable die attach by the eutectic with mechanical scrub method. Each of the three primary functions of picking, placing and scrubbing, of both the pre-form and die, are performed with a single tool head. Precise tool motions in all three axes are operator driven by a single lever micro-manipulator, which also triggers switching between vacuum pick-up and scrub sequences. Work piece pick-up and place areas are moved into position alternately by sliding the workholder on the work platform. A delay before scrub can be programmed as needed.

Programming and Interface :

All machine configuration constants are programmable at the machine panel, prompted by a series of "screens" displayed on an LCD. Input is via a combination of selector switch and tool vertical position, measured by encoder. These values together with sequence status are displayed during bonding.

Definitions of Models of this Series

|

7300C

|

Ultrasonic Scrub, Single Collet Eutectic Die Bond Machine

Values are programmed for scrub time and ultrasonic power.

|

|

7316C

|

Motorized Scrub, Single Collet Eutectic Die Bond Machine

Values are programmed for scrub velocity, distance, direction and number of cycles.

|

|

7327C

|

Motorized Scrub, Hexa-Collet Eutectic Die Bond Machine

Six different die collets are held on the tool head simultaneously. Advance to successive die collets is by pushbutton switch on the manipulator control. Values are programmed for scrub velocity, distance, direction and number of cycles. |

Features Available for this Series

|

-43B:

|

Superimposed Microscope Attached Reference Target

A visual reference is added to the microscope view to aid the precision placement of die. Custom reference targets are available on request through separate order.

|

|

-72E:

|

External View TV Camera

Color external view TV camera with magnification adjustment within a range of 30X to 55X. Flat screen monitor & power supply included.

|

|

-79E:

|

Adjustable Height Work Platform

Work platform with adjustable height for variable package thickness.

|

|

-81:

|

Adjustable Height Work Platform with Planarity Control

Work platform with adjustable height for variable package thickness and three point adjustment control of work surface planarity. (recommended)

|

Mechanical

|

Scrub Action:

7300C

7316C, 7327C

|

Y axis; programmable

ultrasonic; 63 kHz nominal; up to 5 Watts; scrub time up to 999 ms

motor driven; cycles up to 50; velocity settings from 1 to 20; stroke from +/-.001" to +/-.020"; settable for forward scrub, rearward scrub or both

|

|

Bond Force:

7300C

7316C, 7327C

|

manually adjustable

10 – 130 grams

10 – 75 grams

|

|

Bond Tool:

Diameter

Length

|

fitted die collet

1/16"

1/8" (available on special order; 7316C & 7327C)

0.625" (7300C & 7316C)

0.4375" (7327C)

|

|

Tool Heat:

|

adjustable radiant heater w/ steady state control (not available on 7327C) |

|

X/Y/Z Manipulator:

X axis

Y axis

Z axis

Z encoder

Brakes

Balance

|

pivoted motion; 8 : 1 reduction; 0.625" travel

linear motion; 8 : 1 reduction; 0.625" travel

pivoted motion; 3 : 1 reduction; 0.688" travel

0.001" resolution

Y & Z axes; during scrub sequence

counterweighted & sprung; biased away from work |

|

Work Elevation:

|

5.000" nominal above tabletop |

|

Work Platform:

Height

Attachment

|

(standard) fixed @ 2.688" below nominal work elevation

(available) adjustable @ 0.094" above to 0.531" below fixed height

bolt on |

|

Forming Gas:

Flow gauge

|

0 – 10 Standard Cubic Feet per Hour; 100 psi max.

1/8" FNPT fittings

|

Electrical Software and Hardware

|

Process Control:

|

West·Bond Part No. 8100 CPU w/ Motorola 68000 microprocessor, 256 KB of nonvolatile RAM |

|

Program Buffers:

|

10 total for each of the scrub parameters |

|

Display:

|

4-line, 40-character LCD |

|

Z encoder:

|

measured down from home position |

ESD Protection

Protection against Electrostatic Discharge is implemented by finishing exposed tool assemblies and other moving parts by Electroless Nickel plating, which is conductive; and all exposed painted parts with a powder-coated paint that is dissipative (1 - 10 MΩ).

Machine Configuration

|

Microscope:

|

Olympus SZ51-60E or Nikon SMZ660 (recommended; not included) |

|

Illumination:

|

"Luxuray" #10265.00 or #10265.01 (recommended; not included) |

|

Die Collet:

|

should be ordered directly from tool manufacturers (not included) |

|

Work Holder:

|

workholders also are not included, and are priced separately. Quite a large number of previously designed special work holders, both heated and unheated, are available for selection from the Work holders Product List on our Website: Those with Status of Current can be selected for delivery in the same time span as the machine, while those of Status Available Not Stocked must be ordered separately. Workholders for new work pieces requiring custom design and fabrication will be quoted upon receipt of drawings and samples: These must be ordered on separate purchase orders.

|

|

Temperature Controller:

|

West·Bond K~1200D (recommended; not included)

|

Services Required

|

Compressed Air:

|

50 psi; dry air

regulating valve & pressure gauge provided

|

|

Vacuum:

|

shop vacuum (3 – 25 in/Hg)

|

|

Electrical:

|

50-60 Hz, single-phase, either 115 VAC or 230 VAC; selected automatically. A fuse and three-prong power cord connector is provided for 115 VAC: For 230 VAC, these must be changed to conform to local requirements. |

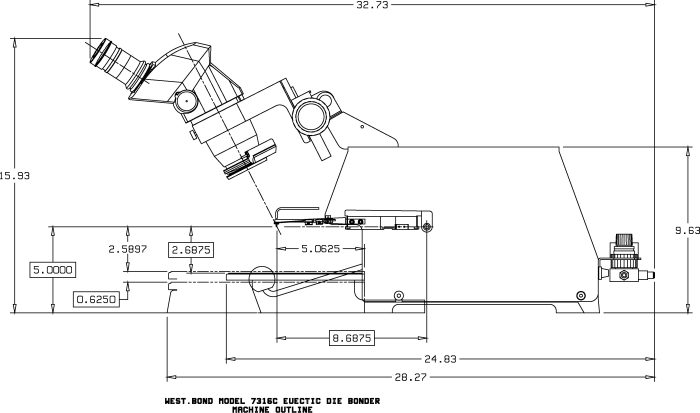

Weights & Dimensions

|

Uncrated:

|

51 lbs; w/o platform

57 lbs; w/ standard platform

67 lbs; w/ adjustable platform

|

|

Crated:

|

120 lbs; w/ accessories |

| |

|

|

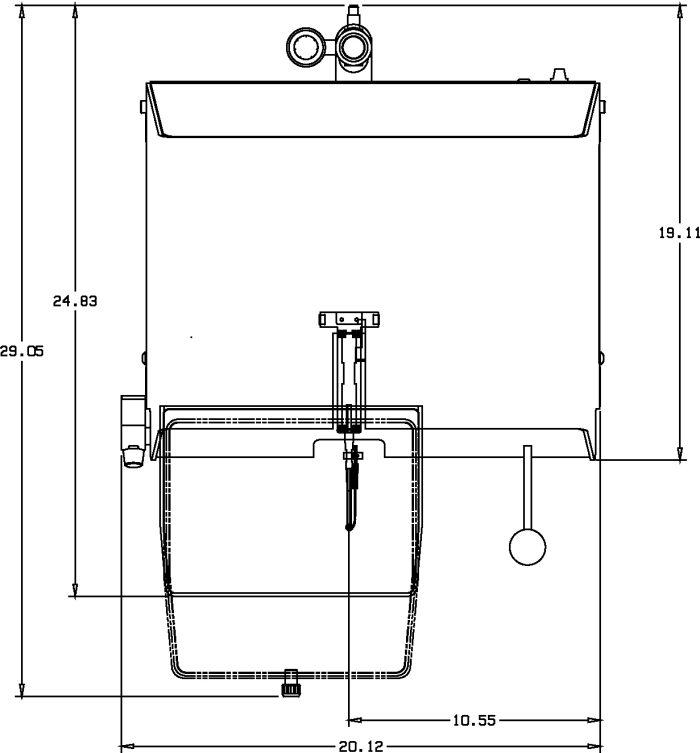

Overall Dimensions:

Width

Depth

Height

|

20.12"

29.05"

11.66" w/o microscope |

Dimensional Drawings

Top Top

1551 S. Harris Court, Anaheim, CA 92806 Anaheim, CA 92806

Phone: 714.978.1551  Fax: 714.978.0431 Fax: 714.978.0431

Products | News | Events

| Support | Corporate | Contact Us | Universities | Home

Manual Die Bonders | Manual Wire Bonders | Semi-Automatic Wire Bonders | Automatic Wire Bonders | Pull Test Machines

|